PURRO filters are produced in carefully selected European factories, meeting strict production technology norms and using advanced technologies. High quality of our products results from using automated production techniques, enhanced with innovations that improve production process.

Before launching, all PURRO filters are tested in laboratories on cutting edge laboratory devices and machines. Specialists from Quality Management Department control if PURRO products meet all the highest norms and standards which are in force on the automotive spare parts market and provide customers with reliability and safety of use.

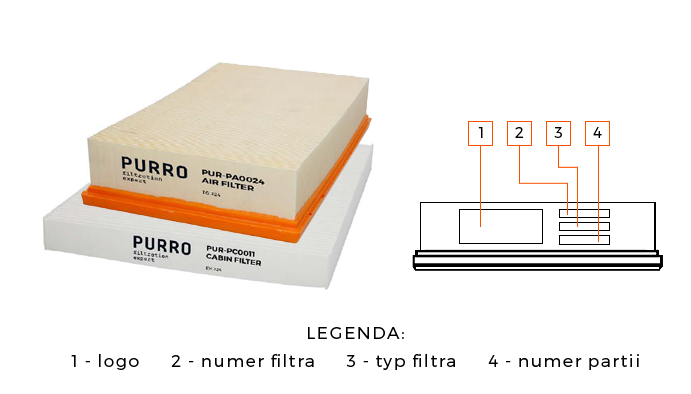

In order to guarantee permanent level of quality, spot checks of delivered products and quality of their workmanship and materials used for production are performed. Individual marking of products and batches makes it possible to control the whole process. Additionally, permanent marking of elements makes it impossible to forge the products, and ensures guarantee of originality of PURRO products.

Factories, producing PURRO filters meet the strict ISO 14001:2015 and IATF 16949 norms. The same quality standards apply to all PURRO products in each and every stage of their production. Numerous tests confirm compliance with industry standards, including: ISO 4548-1 – differential pressure/flow characteristics,

PURRO filters ensure travelling in comfortable conditions. Concern about the health and safety of passengers is our priority. Thanks to PURRO, the interior of every car will be a dirt-, bacteria- and mould-free zone.

Our products are manufactured with care for the environment. We are constantly upgrading our production systems and selecting production materials which make PURRO products environmentally friendly.